We are Experts in Slurry Waste Recycling.

Trenchless Slurry Management

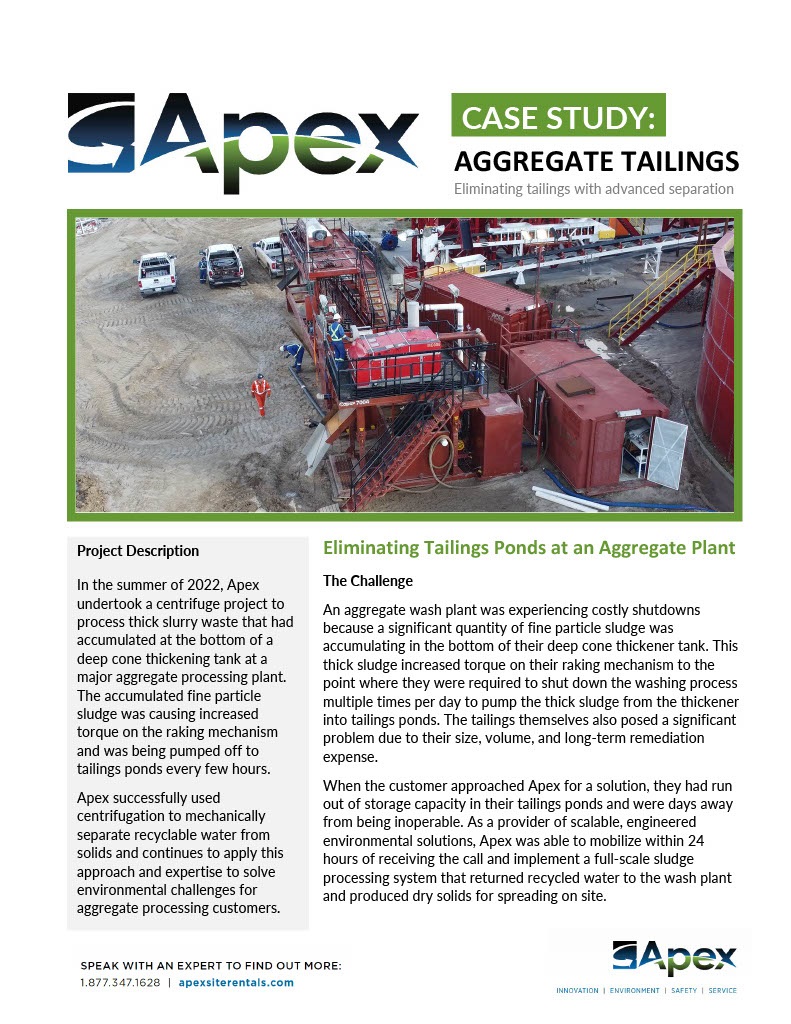

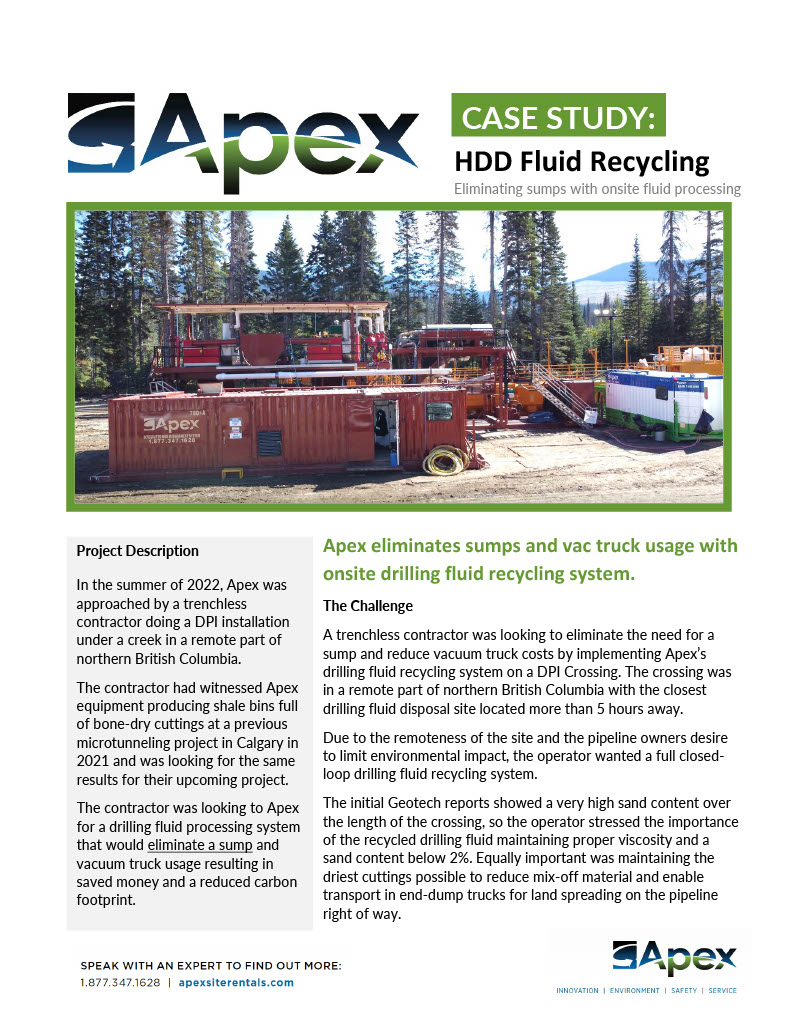

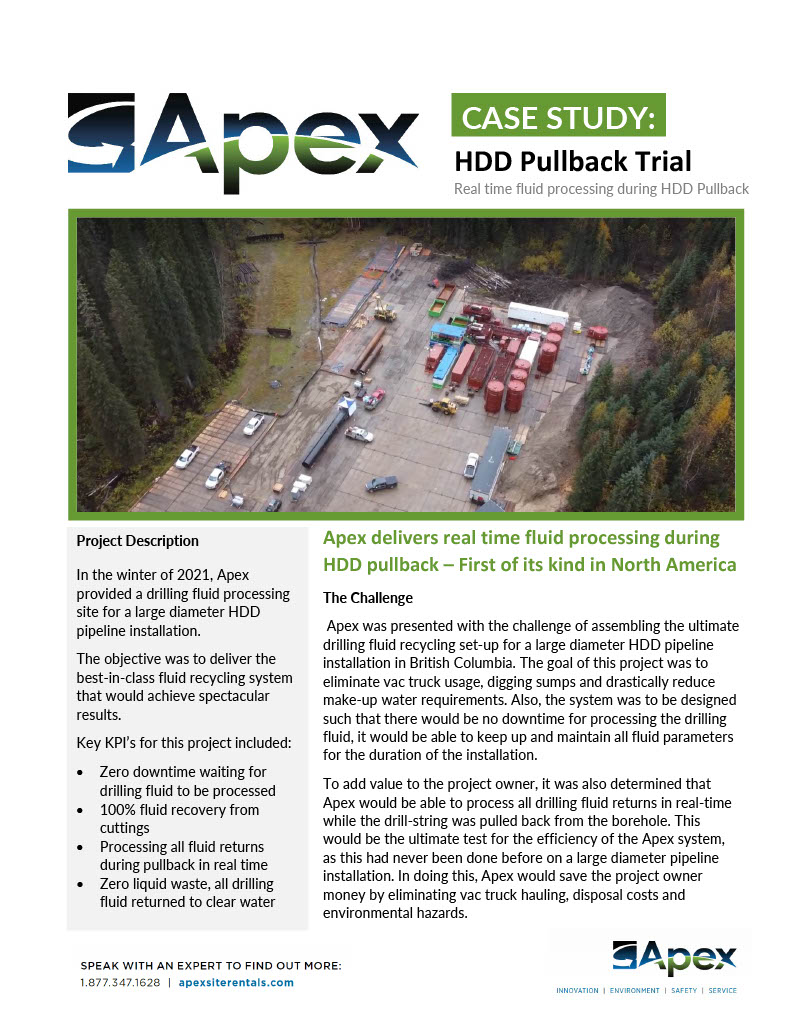

All trenchless technologies have one thing in common, they produce liquid waste. Whether you’re Microtunneling, Direct Pipe or Horizontal Directional Drilling, your project will benefit from an optimized drilling fluid recovery program. Our expertise lies in eliminating liquid waste from your trenchless project with the most advanced and diverse fluid processing on the market.

We can design a solution to address individual concerns, be it footprint, remote location, varied ground conditions or extreme weather, all while maintaining drilling fluid properties and waste mitigation at the forefront.

Apex will add value to your Trenchless Project by:

- Reducing Waste Disposal Costs

- Reducing Green House Gas Emissions

- Reducing make-up water

- Reducing fluid additive costs

- Improving drilling fluid rheology

- Reducing equipment maintenance costs

Hydrovac Waste Processing

Apex has mobile hydrovac slurry processing systems that discharge clean water along with reusable solid material for construction purposes. Our modularized system is designed for fast installation, year-round operation and can even fit on the most compact job sites. Dewatering hydrovac slurry on-site allows for significant reduction in waste volume, disposal costs, transport costs and the ability for water reuse.

Deep Foundation Slurry Management

Apex has the equipment and expertise to reduce the large amounts of liquid waste generated by deep foundation drilling. More specifically, we add value to your deep foundation project by ensuring the support fluid properties are managed, tested, and disposed of in the most efficient and sustainable manner possible.

Our equipment is scalable and compact to work on locations with limited space.

We will deliver support fluid that is processed onsite, in real time and that meets all required criteria for reuse and concreting. When it comes time for disposal, we will again deliver value by separating the slurry waste into clean water and dry, stackable solids.

We ensure that the support fluid properties are maintained during the duration of the excavation and then is disposed in the most economical and sustainable method possible upon project completion.

The Apex Slurry Management advantage:

- Maintain excavation stability

- Maintain fluid properties

- Ensure concrete integrity

- Manage suspended particles

- Reduce waste disposal costs

- Increase environmental sustainability